Centrifugal Compressors

Industrial turbo compressors to meet the needs of the metallurgical, oil and gas and chemical industries.

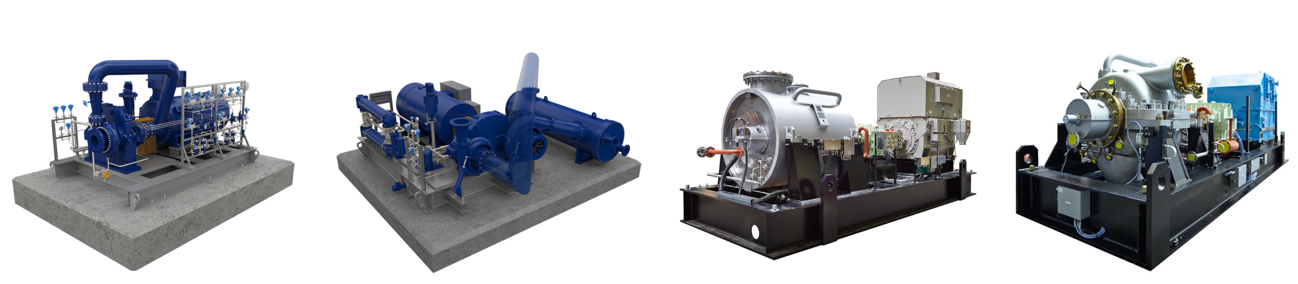

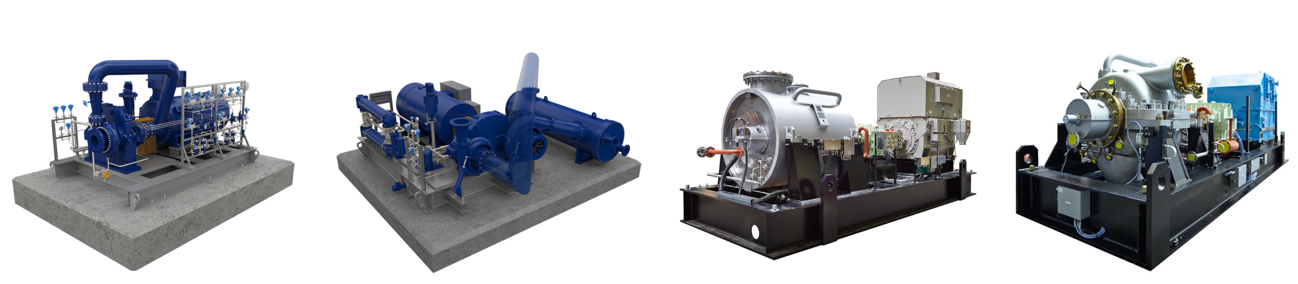

Howden offers a comprehensive range of Industrial Centrifugal Turbo Compressors up to 600,000 m3/h, with the flexibility to address the specific requirements for your application. Our standardized units with modular design ensure low life cycle and investment cost and short delivery times. Metallurgical, chemical and petrochemical plants are the most common applications for our solutions.

Our product range consists of single and multistage compressors to suit a wide range of industrial applications. Find out more about our single stage range, manufacturing and digital controls in our video.

Multiple chemical production processes require the movement and compression of gases. Often these gases are corrosive, erosive and sticky in nature gases and necessitate highly engineered compressors that are suitable for reliable operation in such harsh environments.

Howden's KK&K and CKD branded compressors set the benchmark for safety and reliability, at the lowest lifecycle costs.

Typical processes served

Sulphur is the world’s most used chemical and versatile mineral applied as an essential intermediate in many processes in the chemical and manufacturing industries.

Sulphuric acid plants (SAP) contribute to fertilisers and caprolactam/oleum production, after metallurgical smelters to clean off-gases (desulphurisation process), within acid leaching (e.g. nickel production)and within petrochemical or refining acting as acid recovery.

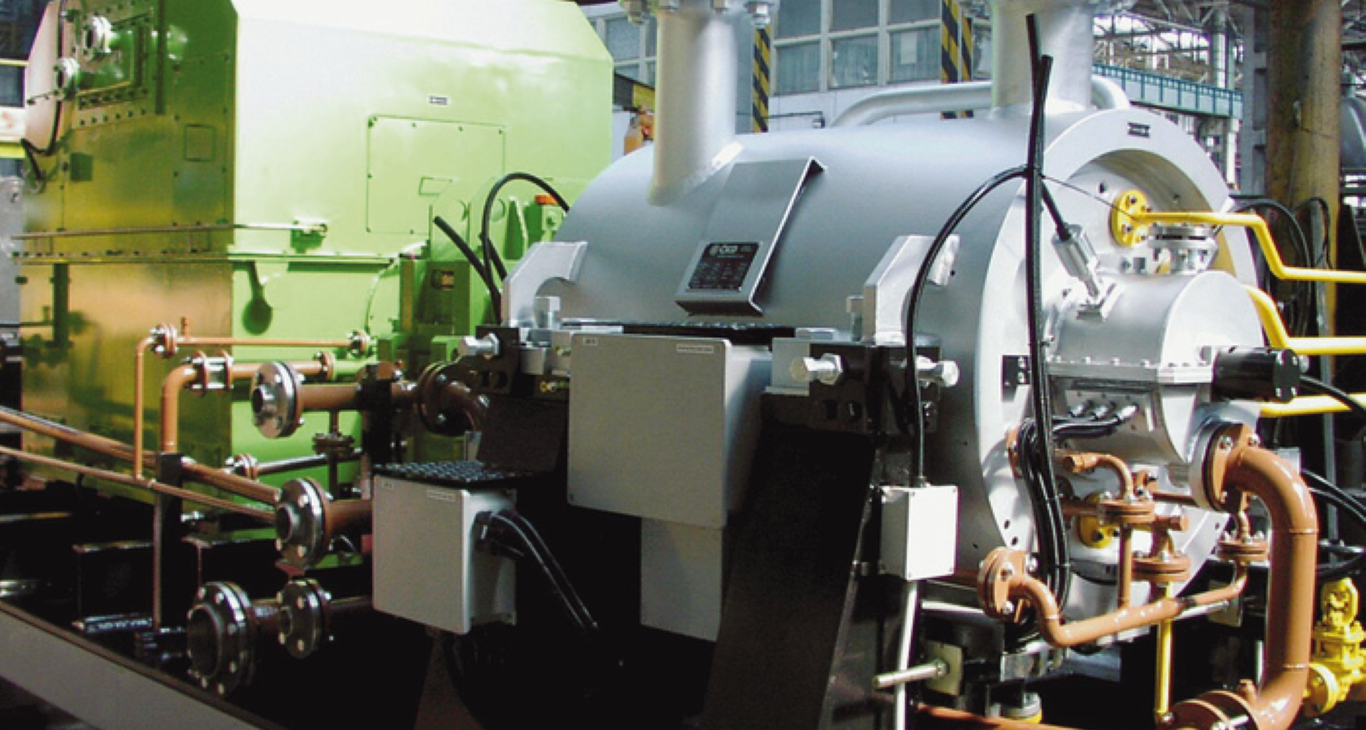

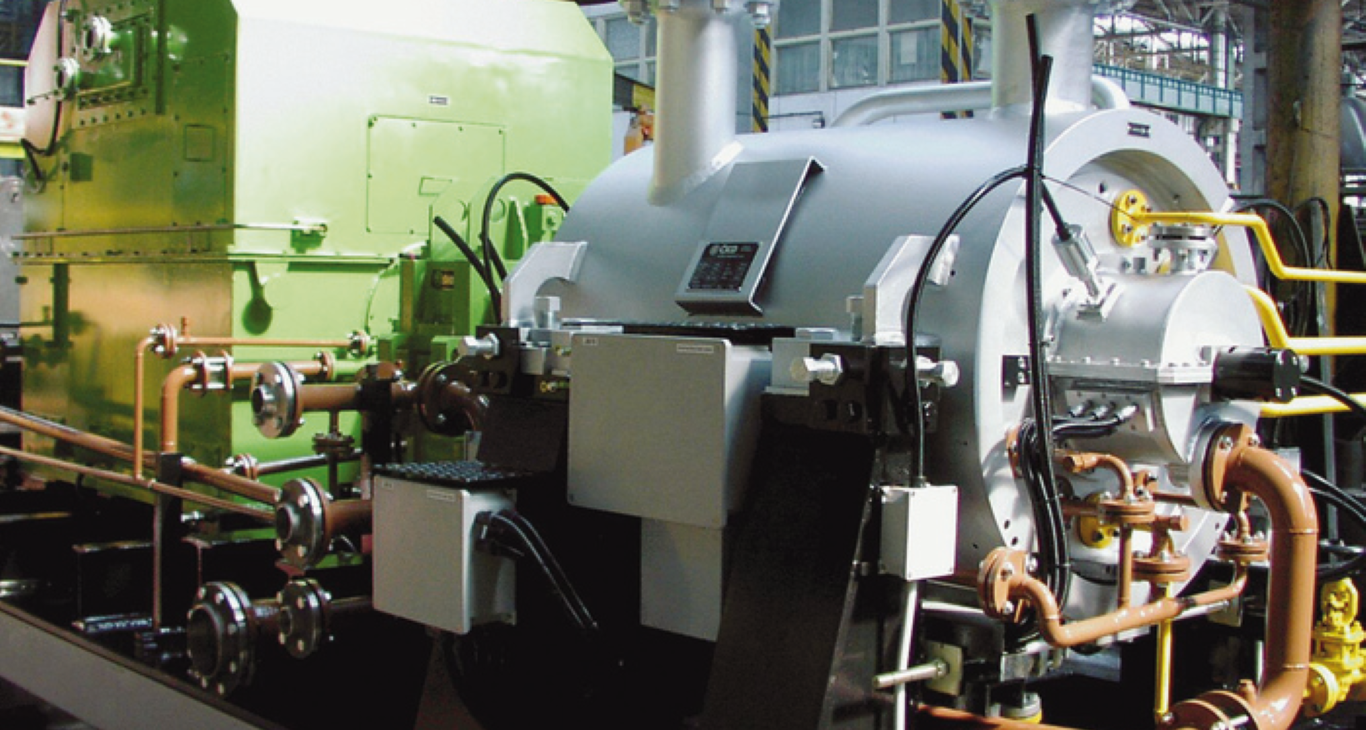

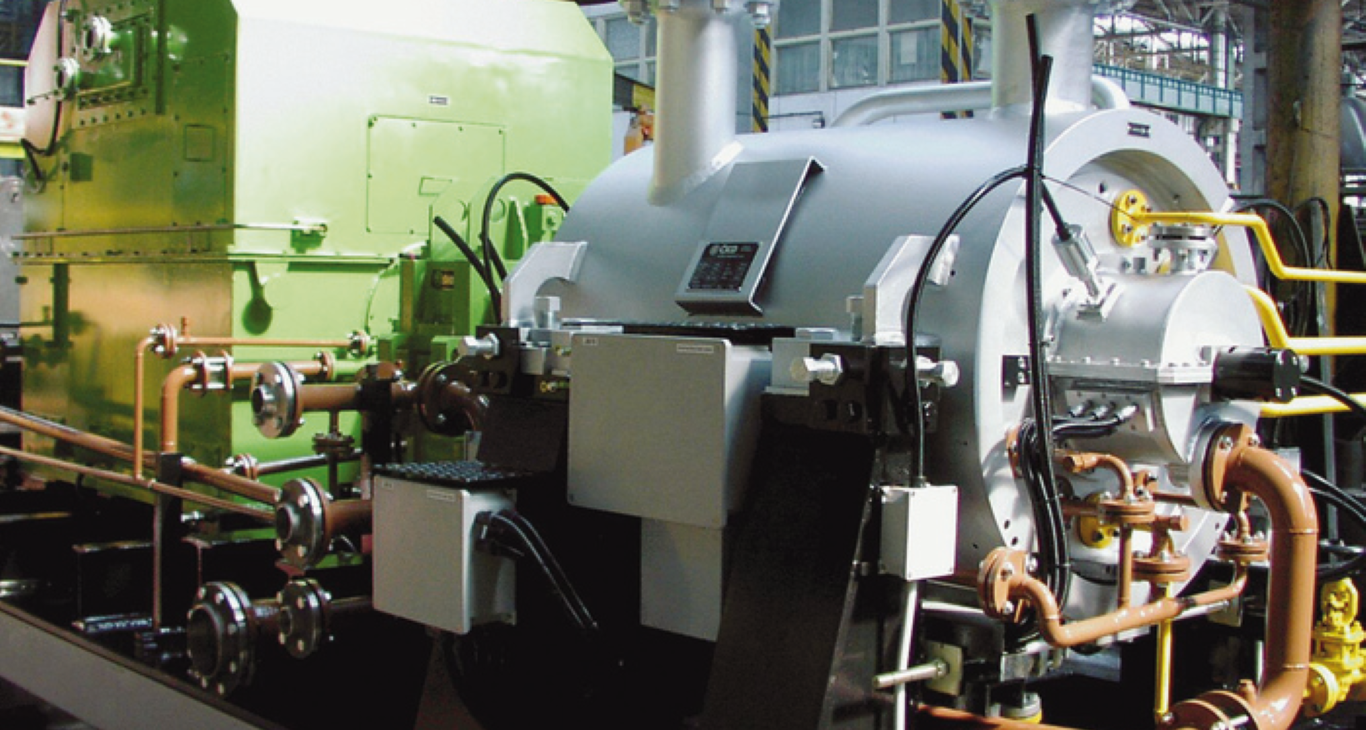

Howden's KK&K sulphuric acid blowers play an integral part in the production of sulphuric acid. They are designed to withstand the high demands caused by unbalance, corrosive attack and erosion and set the standards for efficiency, reliability and rugged design.Applicable products

Carbonised coal in the form of coke is as an important source of energy, which is primarily used as a reducing agent in metal extraction. During the coke-making process a large amount of crude coke oven gas is produced. This crude gas requires treatment to form clean fuel gas by means of cooling, filtration and the extraction of valuable products.

Howden has been manufacturing coke gas exhausters since 1902 through the Kühnle, Kopp & Kausch brand. As a technology leader, Howden sets the standards for coke gas exhausters in terms of efficiency, reliability and sturdy design, engineering the blower to cope with typical operating conditions involving toxic and hazardous gases with adhesive content.

Relevant products

Many industrial industrial processes involve evaporation, crystallization or distillation.

These processes are high consumers of energy, typically within heat and steam generation. Our compressors can increase the efficiency of such processes through mechanical vapor recompression, which recovers heat and recycles it to process thereby reducing energy requirements.

Howden has a significant expertise in this application and has a wide product portfolio, including our centrifugal compressors, capable to addressing the engineering requirements.

Often our compressors are able to achieve the target temperature rise in a single stage and due to their robust design and advanced materials can withstand severe operating conditions.

Typical processes:

Refrigeration or process cooling is a key component of some petrochemical production processes.

The process of cooling usually involves large volumes of gas and compression over multiple stage.

Typical process served

The Direct Reduced Iron (DRI) process is known for producing high quality iron and steel products in a wide variety of furnaces. Being based on gas rather than coke, it is also gaining popularity as a method of decarbonising the metals industry when combined with hydrogen as a fuel gas to produce green steel.

Howden's single stage and multistage integrally geared compressors are used in various DRI applications to enable CO2 reduction within the steel making process.

Multiple chemical production processes require the movement and compression of gases. Often these gases are corrosive, erosive and sticky in nature gases and necessitate highly engineered compressors that are suitable for reliable operation in such harsh environments.

Howden's KK&K and CKD branded compressors set the benchmark for safety and reliability, at the lowest lifecycle costs.

Typical processes served

Sulphur is the world’s most used chemical and versatile mineral applied as an essential intermediate in many processes in the chemical and manufacturing industries.

Sulphuric acid plants (SAP) contribute to fertilisers and caprolactam/oleum production, after metallurgical smelters to clean off-gases (desulphurisation process), within acid leaching (e.g. nickel production)and within petrochemical or refining acting as acid recovery.

Howden's KK&K sulphuric acid blowers play an integral part in the production of sulphuric acid. They are designed to withstand the high demands caused by unbalance, corrosive attack and erosion and set the standards for efficiency, reliability and rugged design.Applicable products

Carbonised coal in the form of coke is as an important source of energy, which is primarily used as a reducing agent in metal extraction. During the coke-making process a large amount of crude coke oven gas is produced. This crude gas requires treatment to form clean fuel gas by means of cooling, filtration and the extraction of valuable products.

Howden has been manufacturing coke gas exhausters since 1902 through the Kühnle, Kopp & Kausch brand. As a technology leader, Howden sets the standards for coke gas exhausters in terms of efficiency, reliability and sturdy design, engineering the blower to cope with typical operating conditions involving toxic and hazardous gases with adhesive content.

Relevant products

Many industrial industrial processes involve evaporation, crystallization or distillation.

These processes are high consumers of energy, typically within heat and steam generation. Our compressors can increase the efficiency of such processes through mechanical vapor recompression, which recovers heat and recycles it to process thereby reducing energy requirements.

Howden has a significant expertise in this application and has a wide product portfolio, including our centrifugal compressors, capable to addressing the engineering requirements.

Often our compressors are able to achieve the target temperature rise in a single stage and due to their robust design and advanced materials can withstand severe operating conditions.

Typical processes:

Refrigeration or process cooling is a key component of some petrochemical production processes.

The process of cooling usually involves large volumes of gas and compression over multiple stage.

Typical process served

The Direct Reduced Iron (DRI) process is known for producing high quality iron and steel products in a wide variety of furnaces. Being based on gas rather than coke, it is also gaining popularity as a method of decarbonising the metals industry when combined with hydrogen as a fuel gas to produce green steel.

Howden's single stage and multistage integrally geared compressors are used in various DRI applications to enable CO2 reduction within the steel making process.

Relevant products

Formed in 1899 and part of Howden since 2017, Kühnle, Kopp & Kausch (KK&K) compressors serve gas applications within industrial production such as chemicals and metals.

Available as single stage and multistage the compressors can serve high flow requirements up to 600,000 m3/h and pressure rise of up to 3.5 within a single stage or 6 for multistage.

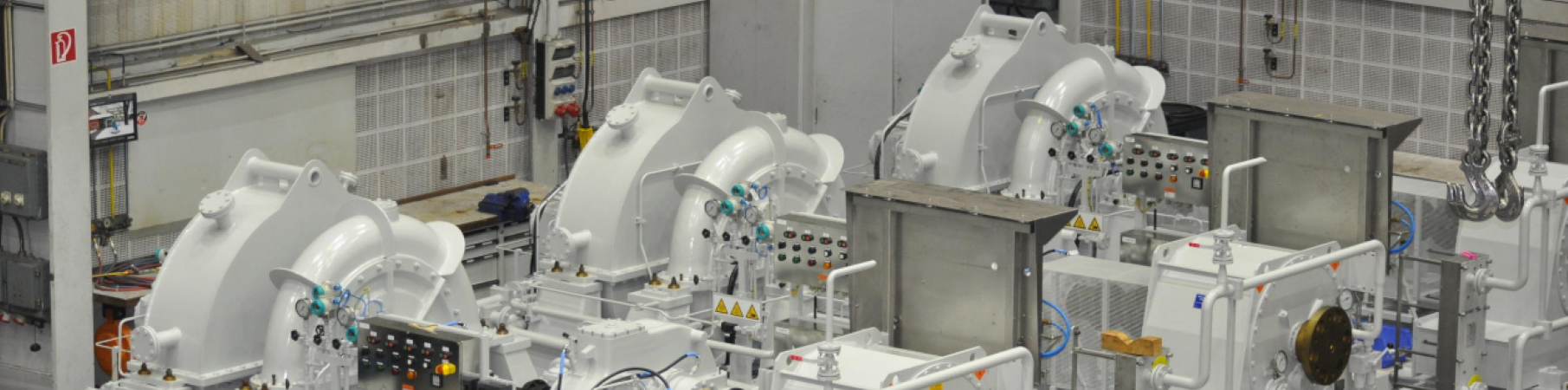

Formed in 1927 and part of Howden since 2013, Českomoravská-Kolben-Daněk (CKD) compressors serve gas applications within the oil & gas, petrochemical, power and steel industries.

Available in a multistage design, the compressors can serve flow requirements up to 1700,000 m3/h and discharge pressures of up to 20 MPa.

Howden’s single stage centrifugal compressors are from the Kühnle, Kopp and Kausch brand. The model range serves applications requiring flows of between 3,000 m3/h and 600,000 m3/h with pressure ratios of up to 3.5.

A summary view of our model range:

| Model | Flow (m3/h) | Pressure Ratio | Impeller Dia. (mm) | Drive | Applications |

|---|---|---|---|---|---|

| SF | 15,000-600,000 | up to 3.5 | up to 2240 | Electric or turbine | Gas processes within industrial, chemical and oil & gas production. Mechanical vapor recompression within industrial evaporation processes and SAGD |

| SFG | 5,000-300,000 | up to 3.5 | up to 1120 | Electric or turbine | Gas processes within industrial, chemical and oil & gas production. Mechanical vapor recompression within industrial evaporation processes and SAGD. Air service within industrial and metals |

| ST | 1,500-150,000 | up to 3.5 | up to 900 | Steam turbine (integrated) | Air and gas processes in chemicals production. Spent acid regeneration. Mechanical vapor recompression within SAGD. |

| SL | 15,000-450,000 | up to 1.45 | up to 1800 | Electric or turbine | Coke oven gas |

Howden’s multistage centrifugal compressors are from the Kühnle, Kopp and Kausch and Českomoravská-Kolben-Daněk (CKD) brands. The model range serves applications requiring flows of between 400 m3/h and 200,000 m3/h with pressure ratios of up to 10.0.

A summary view of our model range:

| Model | Flow (m3/h) | Pressure Ratio | Impeller Dia. (mm) | Drive | Applications |

|---|---|---|---|---|---|

| SFG Back-to-Back | 3,000-75,000 | up to 6.0 | up to 560 | Electric or turbine | Various chemical and petrochemical applications. |

| SFG Twin | 3,000-200,000 | up to 6.0 | up to 900 | Electric or turbine | Industrial evaporation processes including Zero Liquid Discharge. Steam Assisted Gravity Drainage. Process air. Converter air. Gas process in Direct Reduced Iron (DRI) and blast furnace gas. Carbon Capture and Storage |

| RS | 400-65,000 | up to 10.0 | up to 700 | Electric or turbine | Process gas within petrochemical production and Chemical/Fertilizers. Refrigeration in petrochemical units. Coke oven gas |

| RV | 400-85,000 400-170,000 (back-to-back) |

up to 10.0 | up to 780 | Electric or turbine | Process gas within petrochemical production and Chemical/Fertilizers. Refrigeration in petrochemical units. Coke oven gas |

Howden’s single stage centrifugal compressors are from the Kühnle, Kopp and Kausch brand. The model range serves applications requiring flows of between 3,000 m3/h and 600,000 m3/h with pressure ratios of up to 3.5.

A summary view of our model range:

| Model | Flow (m3/h) | Pressure Ratio | Impeller Dia. (mm) | Drive | Applications |

|---|---|---|---|---|---|

| SF | 15,000-600,000 | up to 3.5 | up to 2240 | Electric or turbine | Gas processes within industrial, chemical and oil & gas production. Mechanical vapor recompression within industrial evaporation processes and SAGD |

| SFG | 5,000-300,000 | up to 3.5 | up to 1120 | Electric or turbine | Gas processes within industrial, chemical and oil & gas production. Mechanical vapor recompression within industrial evaporation processes and SAGD. Air service within industrial and metals |

| ST | 1,500-150,000 | up to 3.5 | up to 900 | Steam turbine (integrated) | Air and gas processes in chemicals production. Spent acid regeneration. Mechanical vapor recompression within SAGD. |

| SL | 15,000-450,000 | up to 1.45 | up to 1800 | Electric or turbine | Coke oven gas |

Howden’s multistage centrifugal compressors are from the Kühnle, Kopp and Kausch and Českomoravská-Kolben-Daněk (CKD) brands. The model range serves applications requiring flows of between 400 m3/h and 200,000 m3/h with pressure ratios of up to 10.0.

A summary view of our model range:

| Model | Flow (m3/h) | Pressure Ratio | Impeller Dia. (mm) | Drive | Applications |

|---|---|---|---|---|---|

| SFG Back-to-Back | 3,000-75,000 | up to 6.0 | up to 560 | Electric or turbine | Various chemical and petrochemical applications. |

| SFG Twin | 3,000-200,000 | up to 6.0 | up to 900 | Electric or turbine | Industrial evaporation processes including Zero Liquid Discharge. Steam Assisted Gravity Drainage. Process air. Converter air. Gas process in Direct Reduced Iron (DRI) and blast furnace gas. Carbon Capture and Storage |

| RS | 400-65,000 | up to 10.0 | up to 700 | Electric or turbine | Process gas within petrochemical production and Chemical/Fertilizers. Refrigeration in petrochemical units. Coke oven gas |

| RV | 400-85,000 400-170,000 (back-to-back) |

up to 10.0 | up to 780 | Electric or turbine | Process gas within petrochemical production and Chemical/Fertilizers. Refrigeration in petrochemical units. Coke oven gas |

Telephone +49 6233 85 0