Mining

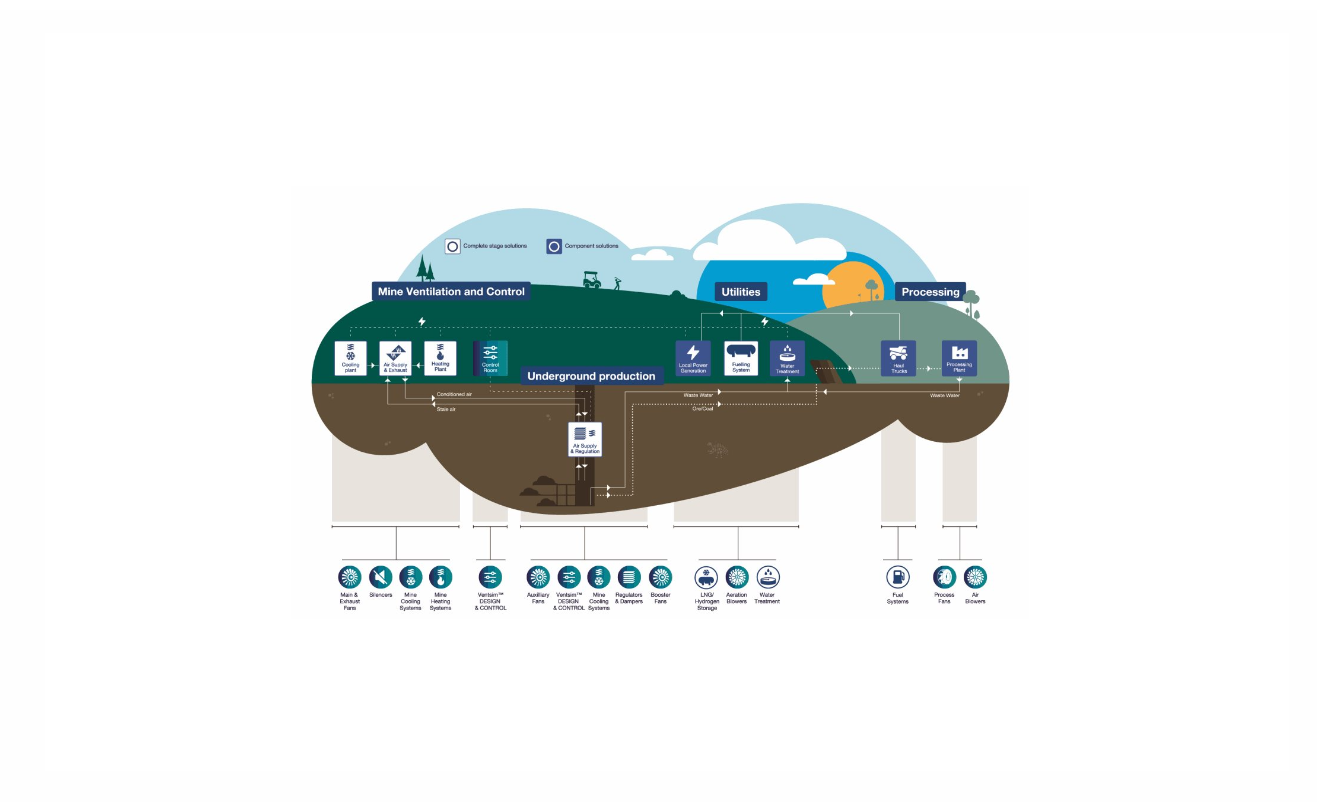

Complete custom-designed ventilation, cooling and heating systems for underground mining applications. Low carbon fuel systems and mine water treatment.

Howden's fan technology provides highly efficient ventilation for safe and underground mining. Heating and cooling solutions maintain an effective working environment and Ventsim software optimises system control. Chart's fuelling and water technology adds to onsite environmental management.

Our fans are relied upon to maintain safe and comfortable conditions for workers within underground mines. Our fans draw large volumes of air through the ventilation system as well as extract waste air and harmful gases from protected spaces.

With a wide range of fan technology, we provide fans for main air or auxiliary air supply. With longstanding experience in ventilation, we offer our expertise to mine operators through ventilation system consultancy and our leading Ventsim software aids designers to understand and develop the best systems attuned to the conditions of each mine.

We have a full project delivery capability which includes the ability to offer turnkey ventilation systems incorporating fans, auxiliary equipment, electrical systems with installation and commissioning.

We can help you optimize operation through Ventsim CONTROL, which adjusts fans and dampers based on gas or air flow sensors. This is an automated solution scalable to Ventilation-On-Demand giving increased safety and operation control and significant energy savings.

Aim: to maintain productive and safe working areas underground by delivering optimised air flows efficiently and reliably.

Typical processes served

With mines located in some of the world’s most extreme climates, temperature control is a vital part of successful operation. This is also impacted by the increasing depth underground mine are reaching, necessitating cooling for safe and productive working environments.

Howden’s cooling and heating technology integrates seamlessly with the whole ventilation system.

A wide range of heaters and cooling systems are available to condition the air for supply within the mine, meaning there is great flexibility in regard to required capacity and other factors such as potential fuel sources, emissions, site configurations and operational efficiencies.

Aim: to provide controlled levels temperature within the mine ventilation system and enable continuous productive and safe working areas.

Typical processes served

Responsible mining involves ensuring wastewater quality standards are maintained to protect the local environment and be compliant with regulations.

Chart has specialist water treatment and reuse technology that enables mines to remove a wide variety of contaminants from mine wastewater.

Aim: to treat wastewater to acceptable standards required for re-use or safe discharge.

Typical processes served

Increased environmental pressure is moving mine operators towards lower carbon energy solutions for off-grid sites.

LNG/Hydrogen Storage & FuellingChart can provide design and supply of complete fuel storage and distribution systems. This includes insulated tanks for liquid storage (LNG/Hydrogen) and regasification systems for supply to gas based power generation units.

On-board Fuel SystemsUsing gas to fuel vehicles reduces greenhouse gas emissions by up to 30% versus conventional liquid fuels. Chart is the world's leading supplier of LNG vehicle fuel systems and our core technologies are applied also to hydrogen powered vehicles.

The fuel system is available for mine haul trucks as a retrofit for existing trucks – conversion for LNG/LH2 or dual fuel - or for integration into new haul trucks.

Aim: to lower mining operations carbon emissions by enabling gas based energy usage.

Typical processes served

Our fans are relied upon to maintain safe and comfortable conditions for workers within underground mines. Our fans draw large volumes of air through the ventilation system as well as extract waste air and harmful gases from protected spaces.

With a wide range of fan technology, we provide fans for main air or auxiliary air supply. With longstanding experience in ventilation, we offer our expertise to mine operators through ventilation system consultancy and our leading Ventsim software aids designers to understand and develop the best systems attuned to the conditions of each mine.

We have a full project delivery capability which includes the ability to offer turnkey ventilation systems incorporating fans, auxiliary equipment, electrical systems with installation and commissioning.

We can help you optimize operation through Ventsim CONTROL, which adjusts fans and dampers based on gas or air flow sensors. This is an automated solution scalable to Ventilation-On-Demand giving increased safety and operation control and significant energy savings.

Aim: to maintain productive and safe working areas underground by delivering optimised air flows efficiently and reliably.

Typical processes served

With mines located in some of the world’s most extreme climates, temperature control is a vital part of successful operation. This is also impacted by the increasing depth underground mine are reaching, necessitating cooling for safe and productive working environments.

Howden’s cooling and heating technology integrates seamlessly with the whole ventilation system.

A wide range of heaters and cooling systems are available to condition the air for supply within the mine, meaning there is great flexibility in regard to required capacity and other factors such as potential fuel sources, emissions, site configurations and operational efficiencies.

Aim: to provide controlled levels temperature within the mine ventilation system and enable continuous productive and safe working areas.

Typical processes served

Responsible mining involves ensuring wastewater quality standards are maintained to protect the local environment and be compliant with regulations.

Chart has specialist water treatment and reuse technology that enables mines to remove a wide variety of contaminants from mine wastewater.

Aim: to treat wastewater to acceptable standards required for re-use or safe discharge.

Typical processes served

LNG/Hydrogen Storage & Fuelling

Chart can provide design and supply of complete fuel storage and distribution systems. This includes insulated tanks for liquid storage (LNG/Hydrogen) and regasification systems for supply to gas based power generation units.

On-board Fuel SystemsUsing gas to fuel vehicles reduces greenhouse gas emissions by up to 30% versus conventional liquid fuels. Chart is the world's leading supplier of LNG vehicle fuel systems and our core technologies are applied also to hydrogen powered vehicles.

The fuel system is available for mine haul trucks as a retrofit for existing trucks – conversion for LNG/LH2 or dual fuel - or for integration into new haul trucks.

Aim: to lower mining operations carbon emissions by enabling gas based energy usage.

Typical processes served

This course will educate participants in fundamental ventilation design and improvement strategies. Using Ventsim, course participants will model and simulate a wide variety of ventilation systems and scenarios. Participants will also learn how to optimise existing ventilation systems, in order to achieve considerable mine cost savings. All participants will receive a 30 day license of the latest version of Ventsim PREMIUM and example files for course work and post course exercises. Participants are required to bring a suitable laptop.

Our product range covers axial, centrifugal and mixed flow fans in a vast variety of configurations for both underground and surface fan applications. They provide versatility, economic advantages, low noise characteristics and outstanding aerodynamic performance.

Axial Fans - primary/main fans

With our vast range of mine heating solutions, Howden sets the standard for heating. Our heaters are capable of burning everything from natural gas and propane to waste oil.

Premium efficiency, serviceability, and low emissions are key to the design of a mine shaft heating system. We ensure every heater is designed to operate safely and effectively in the toughest environments.

Direct-Fired Heaters

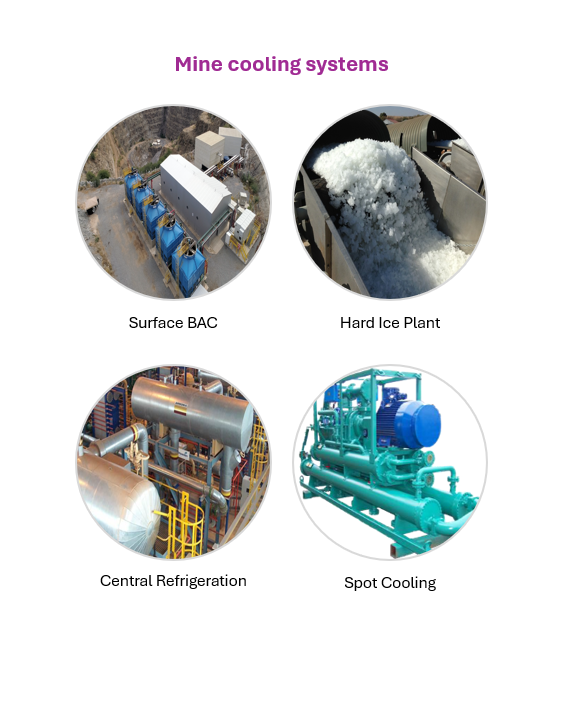

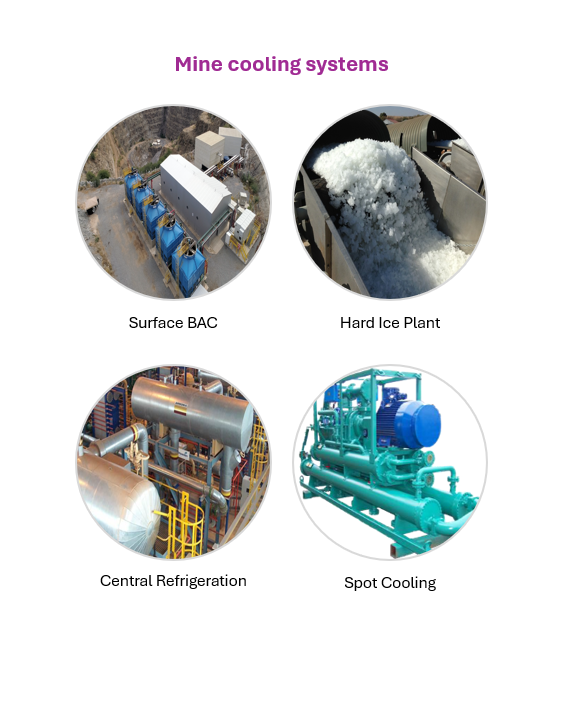

Howden provides complete turnkey mine cooling solutions for surface and underground systems, incorporating in-house technology and equipment from industry-leading partners. A broad and quality portfolio is available from Surface Bulk Air Coolers to Hard Ice Plants, ensuring business continuity and the mine site’s productivity.

Surface Bulk Air Cooling

Howden has a suite of software products available through Ventsim able to enhance ventilation system design, optimise controls to achieve safe and efficient operation and enable effective liquid flows onsite.

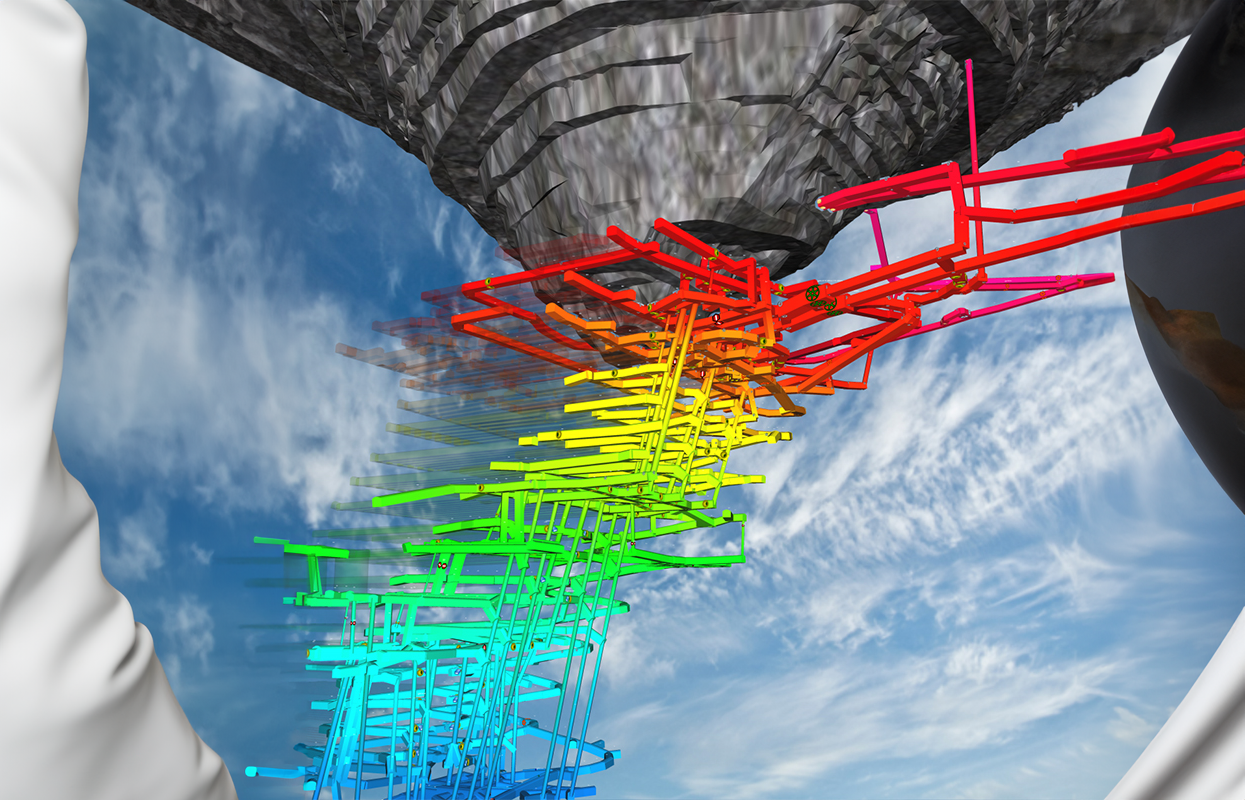

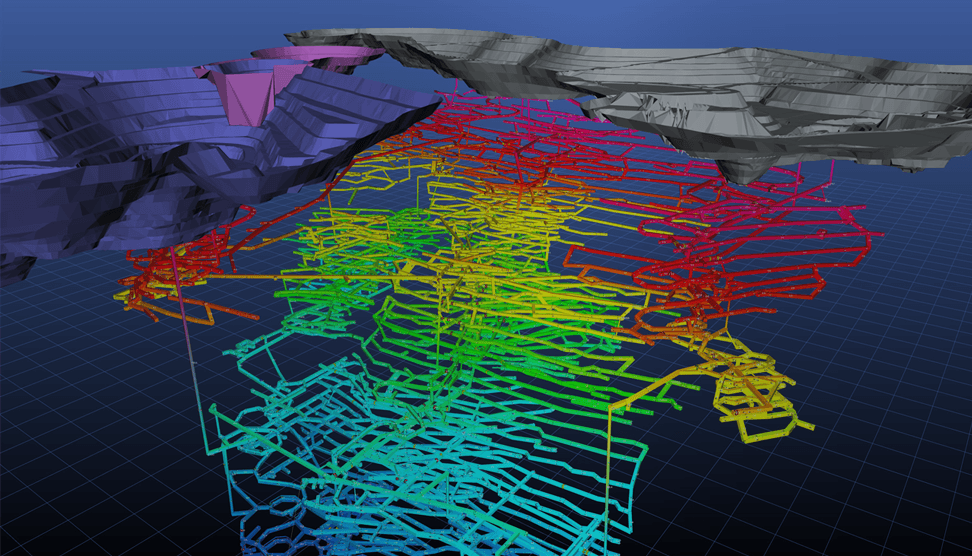

Ventsim DESIGNVentsim software is the ultimate 3D mine ventilation design solution. It allows you to create a 3D model of your tunnels, shafts and raises using your existing 3D mine drawings.

Ventsim CONTROL allows you to operate on a fully automated and optimised mine ventilation solution, including Ventilation-On-Demand, based on vehicle and personnel presence.

A 3-dimensional software package that simulates the pumping and transportation of liquids and slurries through piping systems and networks.

With increasing scrutiny over wastewater discharge to maintain ecological environments around mines, it's important to understand the mix of contaminants present in mine water and have a robust method of treatment.

ChartWater™ offers the most efficient, cost-effective solutions for contaminant removal, including PFAS and arsenic, aerobic biological processes, pH adjustment, ozonation, desalination, odor control and aeration.

Project exampleA gold mine located in Nevada, USA, had arsenic and antimony levels in the raw water well above the United States Environmental Protection Agency’s (USEPA) maximum contaminant level of 0.01 mg/L and 0.006 mg/L respectively.

An AdEdge system was designed, manufactured, and commissioned an arsenic and antimony removal system rated for 1400 gallons per minute (gpm). Following a pilot, which validated the treatment approach and water quality, a full-scale system was commissioned including a coagulation/ filtration system and an adsorption system for the site.

Our product range covers axial, centrifugal and mixed flow fans in a vast variety of configurations for both underground and surface fan applications. They provide versatility, economic advantages, low noise characteristics and outstanding aerodynamic performance.

Axial Fans - primary/main fans

With our vast range of mine heating solutions, Howden sets the standard for heating. Our heaters are capable of burning everything from natural gas and propane to waste oil.

Premium efficiency, serviceability, and low emissions are key to the design of a mine shaft heating system. We ensure every heater is designed to operate safely and effectively in the toughest environments.

Direct-Fired Heaters

Howden provides complete turnkey mine cooling solutions for surface and underground systems, incorporating in-house technology and equipment from industry-leading partners. A broad and quality portfolio is available from Surface Bulk Air Coolers to Hard Ice Plants, ensuring business continuity and the mine site’s productivity.

Surface Bulk Air Cooling

Howden has a suite of software products available through Ventsim able to enhance ventilation system design, optimise controls to achieve safe and efficient operation and enable effective liquid flows onsite.

Ventsim DESIGNVentsim software is the ultimate 3D mine ventilation design solution. It allows you to create a 3D model of your tunnels, shafts and raises using your existing 3D mine drawings.

Ventsim CONTROL allows you to operate on a fully automated and optimised mine ventilation solution, including Ventilation-On-Demand, based on vehicle and personnel presence.

A 3-dimensional software package that simulates the pumping and transportation of liquids and slurries through piping systems and networks.

With increasing scrutiny over wastewater discharge to maintain ecological environments around mines, it's important to understand the mix of contaminants present in mine water and have a robust method of treatment.

ChartWater™ offers the most efficient, cost-effective solutions for contaminant removal, including PFAS and arsenic, aerobic biological processes, pH adjustment, ozonation, desalination, odor control and aeration.

Project exampleA gold mine located in Nevada, USA, had arsenic and antimony levels in the raw water well above the United States Environmental Protection Agency’s (USEPA) maximum contaminant level of 0.01 mg/L and 0.006 mg/L respectively.

An AdEdge system was designed, manufactured, and commissioned an arsenic and antimony removal system rated for 1400 gallons per minute (gpm). Following a pilot, which validated the treatment approach and water quality, a full-scale system was commissioned including a coagulation/ filtration system and an adsorption system for the site.

View and download sales literature, technical manuals and more.

Telephone +44 141 885 7500