Nuclear

Nuclear energy is a vital part of a carbon free future and Howden is a key technology partner to both traditional reactors and emerging small modular designs.

Chart and Howden has industry leading equipment addressing the needs of the nuclear sector. Applied in over 50 years of successful installations, our products and engineering experience enables our customers to operate their processes with the highest levels of efficiency and safety, whether in power and energy generation or research.

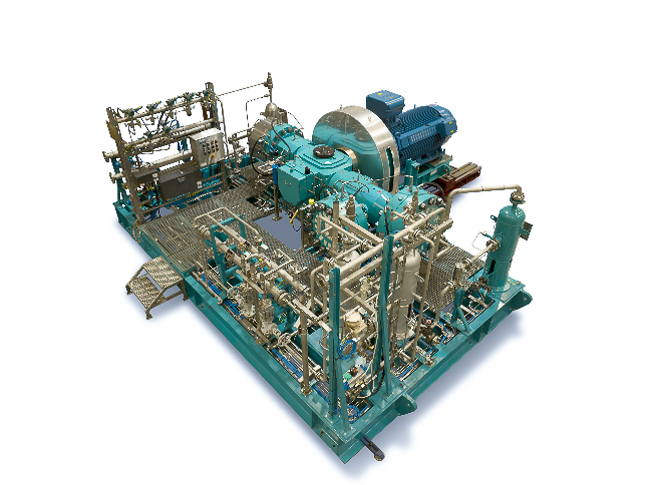

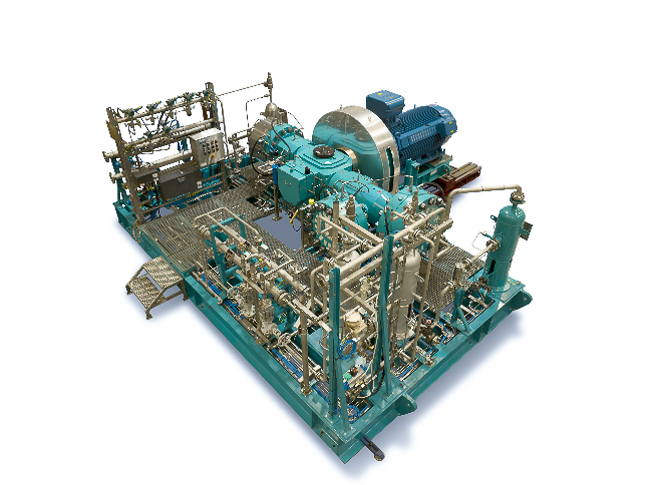

Howden has supplied over 140 gas compressors to PWR plants across Europe, North America, China, Japan, South Korea, India and South Africa. Additionally our gas circulators are used within existing AGR and newer HTGR designs for small modular reactors. Our compressors can also be found within nuclear research facilities such as ITER.

Chart's cryogenic expertise is centred on gas treatment used within nuclear systems and storage in gaseous or liquid form.

Gas circulationGas cooled reactors require circulation of the cooling gas (typically helium or carbon dioxide) for heat transfer - Gas blowers/circulators.

Cover gasCompression of the circulating inert cover gas for moderators - Diaphragm compressors.

Off gasCompression of gaseous waste from the treatment system to tank storage - Diaphragm compressors.

Drying system charge gasMaintains nitrogen pressure within the system used to remove remaining water from the reactor cooling system - Diaphragm/Screw compressors.

Cryogenic storageSafe storage of critical gases for use on site - Tanks, vessels and portable liquid cylinders.

Howden has over 50 years of experience supplying over 15,000 fans within various nuclear facilities from electrical power to fuel manufacturing, waste treatment, research and decommissioning sites.

HVAC/VentilationFresh air, exhaust air, heating, and cooling throughout all areas of the plant. Maintaining a constant negative pressure within controlled areas.

Reactor cavity coolingSafe cooling of the vessel and other structural materials during an accident.

FiltrationThe movement of air in and out of the filtration system used to control air quality by capturing radioactive particles.

Battery Room ExhaustRemoval of unsafe concentrations of gas to maintain reliable atmospheric conditions.

Roof extractionContributing to efficient, safe and comfortable working environment within nuclear facilities.

Dismantling/ContainmentMaintaining a constant negative pressure within controlled areas during dismantling or back-up/emergency situations to ensure radioactive materials are safely contained.

Howden's fans are installed in many nuclear power plants worldwide in association with cooling. Howden and Hudson (both Chart Industries companies) axial fans have long-standing use within utility cooling systems for nuclear energy and Chart is also a supplier of Air Cooled Heat Exchangers (ACHE) and steam heat exchangers.

Reactor cavity coolingSafe cooling of the vessel and other structural materials during an accident - Axial/centrifugal/mixed flow fans.

Utility coolingCooling air for process and utility provide through systems based on cooling towers and air-cooled condensers - Axial cooling fans.

Heat ExchangeConverting reactor heated water to steam for electrical power or thermal use - Shell & Tube heat exchangers.

Heat ExchangeRemoving excess heat from the power production process - Air Cooled Heat Exchangers.

Magnet CoolingCompression within the refrigeration cycle of helium coolant used in fusion reactors - Screw compressors.

Howden has a long heritage of power generation systems throughout industrial applications through our Kühnle, Kopp & Kausch and Peter Brotherhood brands. These turbines provide up to 40MW of power and have installations within nuclear power plants in USA, Belgium and Sweden. Additionally our steam turbines are used across various heavy industries to drive mechanical equipment such as pumps.

PowerElectrical output through steam-based generation.

Energy recoveryEfficient use of waste energy for additional electrical or heat output.

Mechanical driveDrives for major equipment such as pumps.

The combined technologies of AdEdge and BlueInGreen provide a complete portfolio of treatment solutions for removal/treatment of multiple water contaminants.

Wastewater treatmentRemoval of undesired contaminates through filtration, distillation, and vaporisation to a level suitable for release or use in other processes.

Howden has supplied over 140 gas compressors to PWR plants across Europe, North America, China, Japan, South Korea, India and South Africa. Additionally our gas circulators are used within existing AGR and newer HTGR designs for small modular reactors. Our compressors can also be found within nuclear research facilities such as ITER.

Chart's cryogenic expertise is centred on gas treatment used within nuclear systems and storage in gaseous or liquid form.

Gas circulationGas cooled reactors require circulation of the cooling gas (typically helium or carbon dioxide) for heat transfer - Gas blowers/circulators.

Cover gasCompression of the circulating inert cover gas for moderators - Diaphragm compressors.

Off gasCompression of gaseous waste from the treatment system to tank storage - Diaphragm compressors.

Drying system charge gasMaintains nitrogen pressure within the system used to remove remaining water from the reactor cooling system - Diaphragm/Screw compressors.

Cryogenic storageSafe storage of critical gases for use on site - Tanks, vessels and portable liquid cylinders.

Howden has over 50 years of experience supplying over 15,000 fans within various nuclear facilities from electrical power to fuel manufacturing, waste treatment, research and decommissioning sites.

HVAC/VentilationFresh air, exhaust air, heating, and cooling throughout all areas of the plant. Maintaining a constant negative pressure within controlled areas.

Reactor cavity coolingSafe cooling of the vessel and other structural materials during an accident.

FiltrationThe movement of air in and out of the filtration system used to control air quality by capturing radioactive particles.

Battery Room ExhaustRemoval of unsafe concentrations of gas to maintain reliable atmospheric conditions.

Roof extractionContributing to efficient, safe and comfortable working environment within nuclear facilities.

Dismantling/ContainmentMaintaining a constant negative pressure within controlled areas during dismantling or back-up/emergency situations to ensure radioactive materials are safely contained.

Howden's fans are installed in many nuclear power plants worldwide in association with cooling. Howden and Hudson (both Chart Industries companies) axial fans have long-standing use within utility cooling systems for nuclear energy and Chart is also a supplier of Air Cooled Heat Exchangers (ACHE) and steam heat exchangers.

Reactor cavity coolingSafe cooling of the vessel and other structural materials during an accident - Axial/centrifugal/mixed flow fans.

Utility coolingCooling air for process and utility provide through systems based on cooling towers and air-cooled condensers - Axial cooling fans.

Heat ExchangeConverting reactor heated water to steam for electrical power or thermal use - Shell & Tube heat exchangers.

Heat ExchangeRemoving excess heat from the power production process - Air Cooled Heat Exchangers.

Magnet CoolingCompression within the refrigeration cycle of helium coolant used in fusion reactors - Screw compressors.

Howden has a long heritage of power generation systems throughout industrial applications through our Kühnle, Kopp & Kausch and Peter Brotherhood brands. These turbines provide up to 40MW of power and have installations within nuclear power plants in USA, Belgium and Sweden. Additionally our steam turbines are used across various heavy industries to drive mechanical equipment such as pumps.

PowerElectrical output through steam-based generation.

Energy recoveryEfficient use of waste energy for additional electrical or heat output.

Mechanical driveDrives for major equipment such as pumps.

The combined technologies of AdEdge and BlueInGreen provide a complete portfolio of treatment solutions for removal/treatment of multiple water contaminants.

Wastewater treatmentRemoval of undesired contaminates through filtration, distillation, and vaporisation to a level suitable for release or use in other processes.

For more information please download our available marketing literature.

Telephone +44 141 885 7500