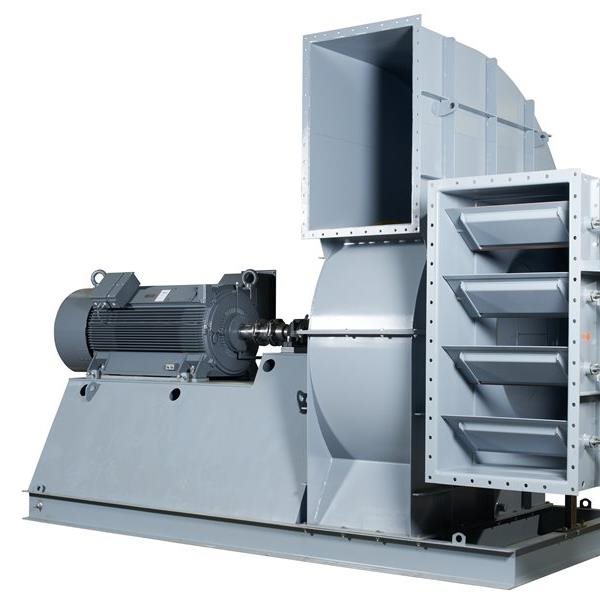

Axial Fans & Centrifugal Fans

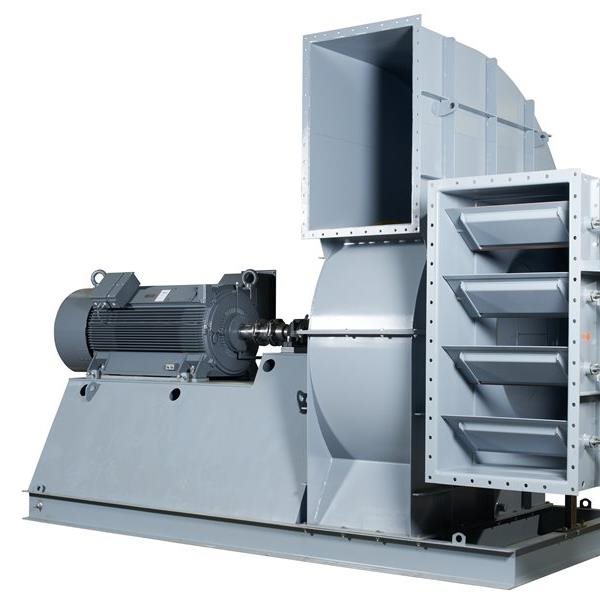

Highly efficient and reliable axial and centrifugal fans from Howden support a wide range of industrial processes requiring the flow of air or gas.

Howden has been designing fans to address industrial demands for over 100 years and continues to lead the world in raising energy efficiency, improving reliability and reducing lifetime costs for our customers. Whether in critical positions in heavy industrial processes or auxiliary applications within light industry, Howden has a fan to fit.

Air is one of the most common ingredients of industrial process and Howden fans have been integral to such processes since the industrial revolution.

Our fans can be used as forced or induced draft to push or draw specified volumes of air through the process. They address a wide range of volumes and pressures, delivering dependable performance to ensure continuous production.

Aim: to provide reliable air flows at selected volumes and pressures into each process stage at the highest efficiency.

Typical processes served

The industries we serve handle many types of gases within production processes and also as a by-product of the process.

Our fans are central to continuous processes handling gases from Nitrogen, Hydrogen and Noble gases to waste gas. They are designed to be durable and deliver high performance, withstanding the effects of corrosive gases, whilst sealing the gas safely within the fan and process.

Aim: to safely and efficiently move gas flows at selected volumes and pressures within and from each process.

Typical processes servedHowden also has a comprehensive range of gas compressors should the gas flow and pressure requirements exceed those suitable for our fans.

Howden fans are relied upon to maintain safe and comfortable conditions for work and transportation, whether it be within industrial facilities or under the ground.

Our fans draw or push large volumes of air through the ventilation system as well as extract waste air, gases and potentially smoke from protected spaces.

Aim: to move required air flows within the system efficiently on a continuous and emergency basis.

Typical processes served

Howden fans are vital part of process and utility cooling systems using air to dissipate heat to atmosphere. Our products are renowned for their excellent efficiency and low noise performance, which enables operators to engineer the best solution relative to cooling capacity requirements, space on site and noise regulations.

Our fans draw or push large volumes of air through air cooled heat exchangers (ACHE/ACHX), air cooled condensers (ACC) and cooling towers. They are also used within heavy machinery to maintain engines are optimal operating temperatures.

Aim: to remove heat from a process or operating equipment efficiently and within permitted noise limits.

Typical processes served

Air is one of the most common ingredients of industrial process and Howden fans have been integral to such processes since the industrial revolution.

Our fans can be used as forced or induced draft to push or draw specified volumes of air through the process. They address a wide range of volumes and pressures, delivering dependable performance to ensure continuous production.

Aim: to provide reliable air flows at selected volumes and pressures into each process stage at the highest efficiency.

Typical processes served

The industries we serve handle many types of gases within production processes and also as a by-product of the process.

Our fans are central to continuous processes handling gases from Nitrogen, Hydrogen and Noble gases to waste gas. They are designed to be durable and deliver high performance, withstanding the effects of corrosive gases, whilst sealing the gas safely within the fan and process.

Aim: to safely and efficiently move gas flows at selected volumes and pressures within and from each process.

Typical processes servedHowden also has a comprehensive range of gas compressors should the gas flow and pressure requirements exceed those suitable for our fans.

Howden fans are relied upon to maintain safe and comfortable conditions for work and transportation, whether it be within industrial facilities or under the ground.

Our fans draw or push large volumes of air through the ventilation system as well as extract waste air, gases and potentially smoke from protected spaces.

Aim: to move required air flows within the system efficiently on a continuous and emergency basis.

Typical processes served

Howden fans are vital part of process and utility cooling systems using air to dissipate heat to atmosphere. Our products are renowned for their excellent efficiency and low noise performance, which enables operators to engineer the best solution relative to cooling capacity requirements, space on site and noise regulations.

Our fans draw or push large volumes of air through air cooled heat exchangers (ACHE/ACHX), air cooled condensers (ACC) and cooling towers. They are also used within heavy machinery to maintain engines are optimal operating temperatures.

Aim: to remove heat from a process or operating equipment efficiently and within permitted noise limits.

Typical processes served

Howden has a fan engineering pedigree developed over hundreds of years through the original Howden brand and those which joined the company such as Sirocco, Sturtevant, Buffalo Forge, Covent, Turbowerke Meissen, Solyvent-Ventec, Voith and Nordisk.

Our fans range from configured to fully engineered to meet a wide variety of customer demands. Our engineering capability means we can have the knowledge, experience and ability to adapt and develop new designs for specific requirements.

All fans are designed to maximize efficient operation with some reaching over 90% depending on application and operation. Fans are compliant with industry standards as required for each application e.g. API, ATEX, Nuclear certifications.

Product Range

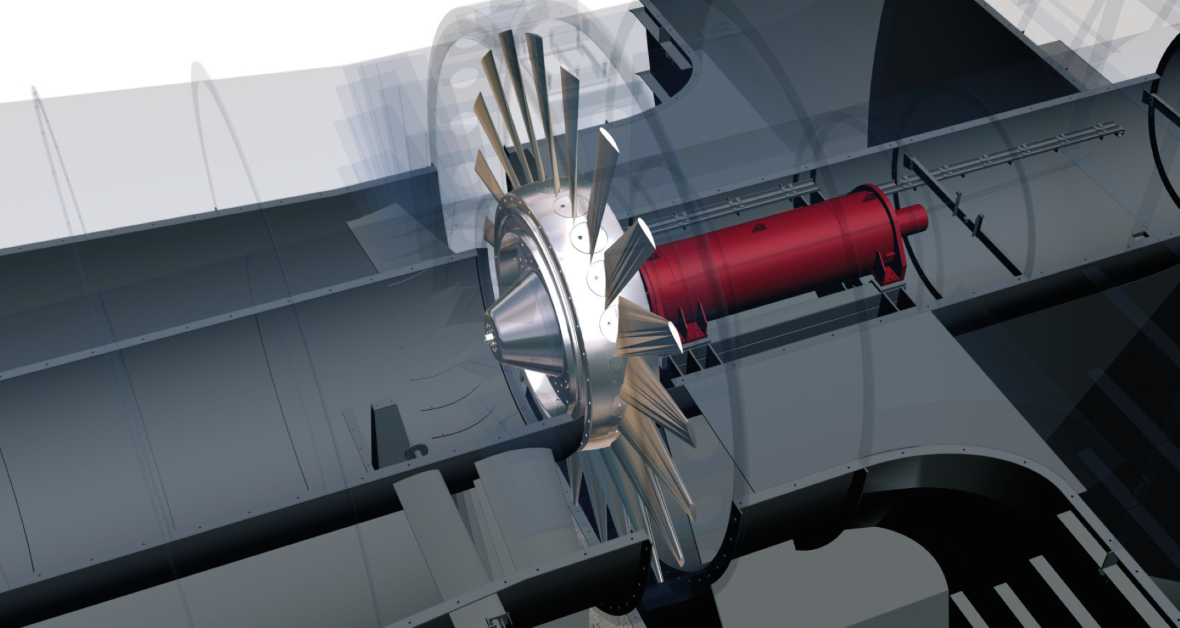

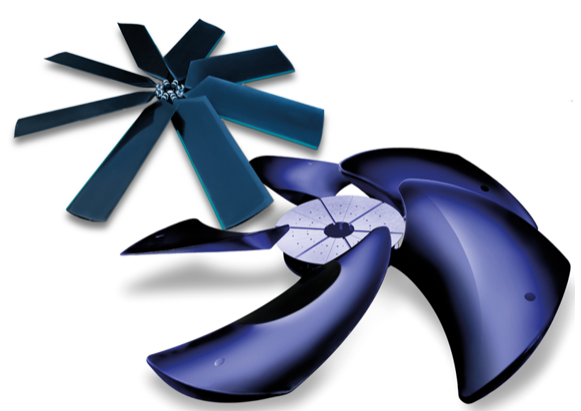

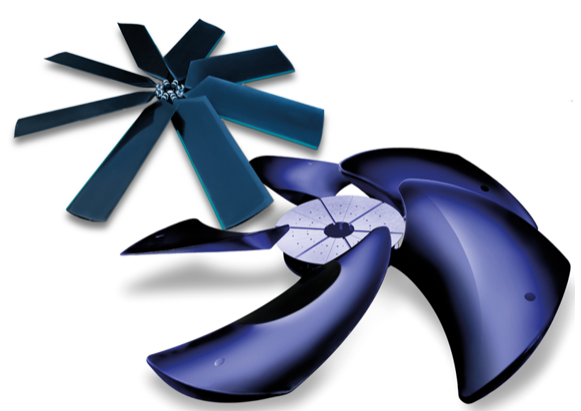

The axial fan range includes a number of products developed across a number of Howden's current and legacy brand to offer comprehensive coverage of industrial flow and pressure requirements.

The range means we can address many applications with alternate configurations vertical or horizontal placement and different flow control options, from manually adjustable-pitch to variable pitch and variable frequency drives.

All fans are manufactured to high standards for efficient operation and low maintenance through reliable service.

Product Range

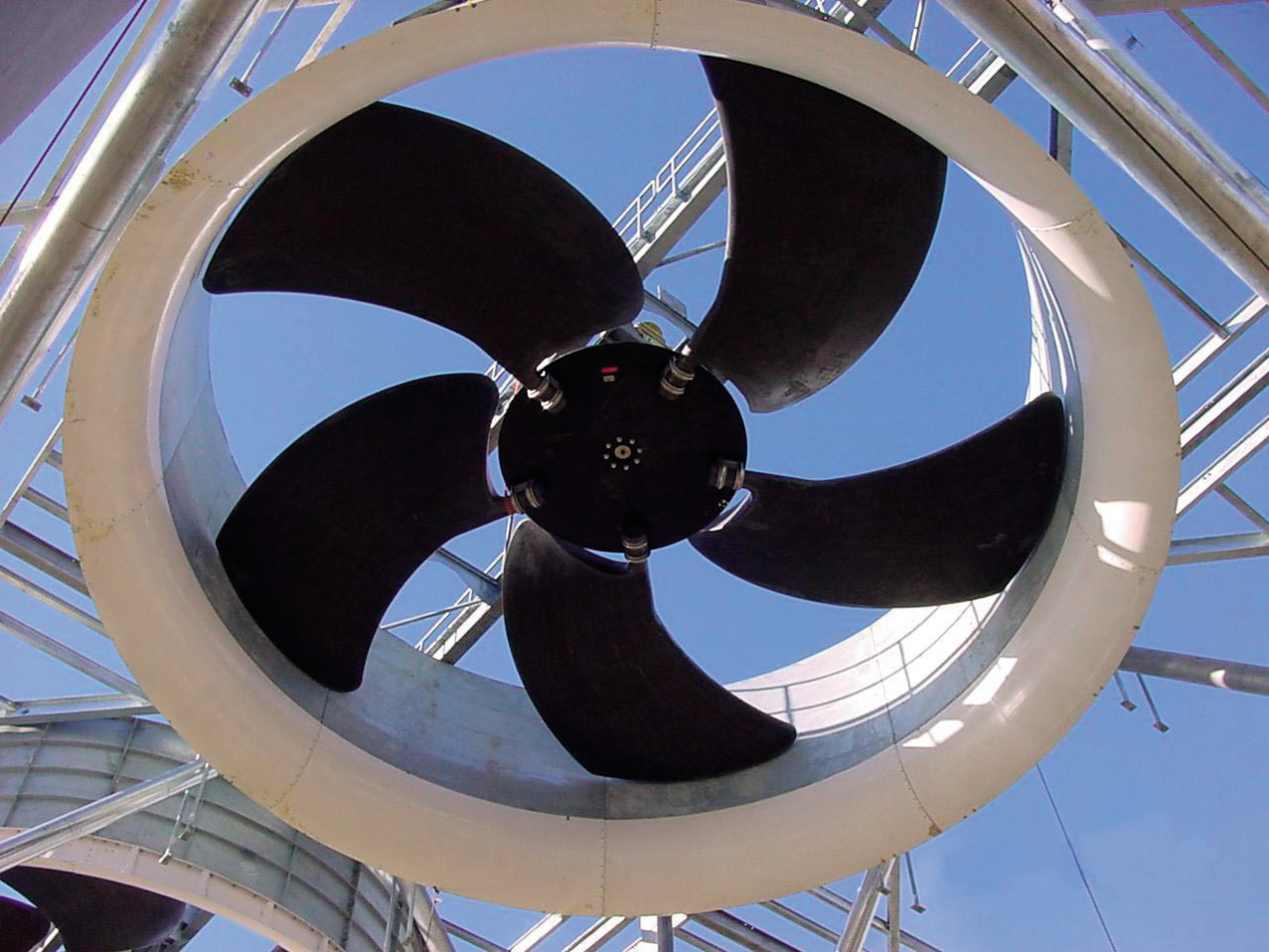

Our range of cooling fans consists of the D, E, SX and FPX series and deliver outstanding performance in efficiency and noise levels across a diverse set of industries from oil & gas and power plants through to light industrial manufacturing plants, data centers, commercial buildings and industrial machinery engines.

The fan range covers a wide performance area with a low pressure drop of up to 250 Pa and high air flow volume of up to 3000 m3/s. They offer low to ultra-low noise capabilities to maximise output within site regulations.

For more information on the range, visit our cooling fans product page and access our marketing literature.

Our fans range from configured to fully engineered to meet a wide variety of customer demands. Our engineering capability means we can have the knowledge, experience and ability to adapt and develop new designs for specific requirements.

All fans are designed to maximize efficient operation with some reaching over 90% depending on application and operation. Fans are compliant with industry standards as required for each application e.g. API, ATEX, Nuclear certifications.

Product Range

The axial fan range includes a number of products developed across a number of Howden's current and legacy brand to offer comprehensive coverage of industrial flow and pressure requirements.

The range means we can address many applications with alternate configurations vertical or horizontal placement and different flow control options, from manually adjustable-pitch to variable pitch and variable frequency drives.

All fans are manufactured to high standards for efficient operation and low maintenance through reliable service.

Product Range

Our range of cooling fans consists of the D, E, SX and FPX series and deliver outstanding performance in efficiency and noise levels across a diverse set of industries from oil & gas and power plants through to light industrial manufacturing plants, data centers, commercial buildings and industrial machinery engines.

The fan range covers a wide performance area with a low pressure drop of up to 250 Pa and high air flow volume of up to 3000 m3/s. They offer low to ultra-low noise capabilities to maximise output within site regulations.

For more information on the range, visit our cooling fans product page and access our marketing literature.

Our service capability encompasses all axial fans from own brands to those of other manufacturers.

For own fan brands we offer a complete range of aftermarket solutions from OEM spare parts, analysis and troubleshooting and general maintenance, to fully engineered upgrades and retrofits for operational performance and life extension.

Our brands include those currently available as new equipment such as Howden and Alphair, but also those acquired over the course of our 160 years of history including Buffalo Forge, Turbowerke Meisen and Nordisk.

Access available marketing literature

Telephone +44 141 885 7500