Articles

Learn more about how our products and services help customers just like you on a daily basis.

People often use the terms ‘cement’ and ‘concrete’ interchangeably. Which is similar to using the words ‘flour’ and ‘cake’ interchangeably. It’s not the same thing. Cement, like flour, is an ingredient.

To make concrete a mixture of portland cement (10-15%) and water (15-20%) make a paste. This paste is then mixed with aggregates (65-75%) such as sand and gravel, or crushed stone. As the cement and water mix, they harden and bind the aggregates into an impenetrable rock-like mass.

Therefore: Cement + Aggregates + Water = Concrete

It is concrete then, that we associate with the strong, durable, structural building material that is used vastly in construction from bridges to buildings and sidewalks.

We answer that, and 5 other things you should know about crude oil. But first, let’s get some facts.And cement is the main binding ingredient within it.

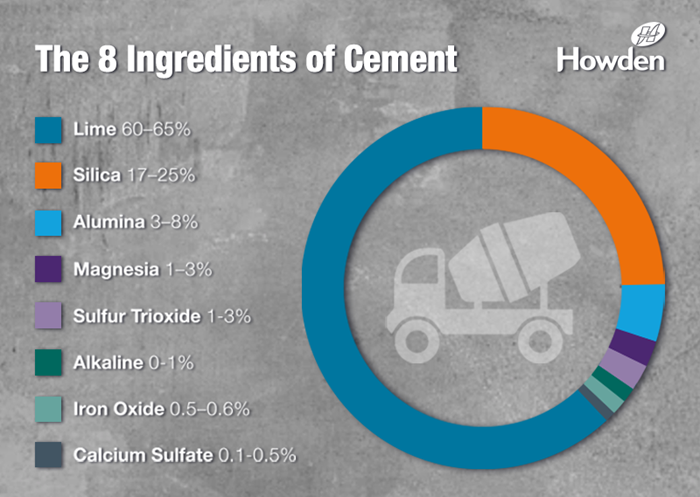

As we know, cement is the main ingredient used to make concrete. But cement isn’t some sort of naturally occurring organic material - it’s manufactured through the chemical combination of 8 main ingredients during the cement production process.

We will take you through each step in the cement production process from the minerals in the ground, to the cement powder that helps make concrete.

The raw materials, mainly limestone and clay, are extracted from their quarries by blasting or drilling using heavy mining machinery. They are moved after extraction and then transported to the crushers via dumpers.

Crushers are capable of handling chunks of quarry rock as large as an oil drum.

The limestone rock is crushed in the first crusher to reduce the rock to a maximum size of about 6 inches. It is then fed into the second crusher with a mixing of clays to reduce particle size below 3 inches. The discharged raw mix (limestone 70%, clays 30%) is conveyed to a raw mill bin for later grinding.

The other raw materials that are used in cement manufacturing, called additives, are also stored in separate bins.

The raw mix and required additives are fed from their bins to the raw mill via blowers for drying and grinding. The raw mill contains two chambers - a drying chamber and a grinding chamber. Hot gases coming from a preheater/ kiln system enters the mill and dries the raw mix materials before it enters the next chamber, which is the grinding chamber.

The grinding chamber contains a certain quantity of ball charge in different sizes ranging from 30mm to 90mm that are used to grind the material. It then feeds to a separator which separates the fine and coarse product. The latter, called reject, is sent to the mill inlet for regrinding. Then, the hot gas and fine materials enter a multistage "cyclone". This is to separate the fine ground materials from the gases. The resulting raw meal, consisting of only the very fine raw meal materials, is conveyed to a concrete silo. From there the raw meal extracted from the silo, now called kiln feed, is fed to the top of the preheater kiln for sintering.

The preheater kiln system consists of a multi-stage cyclone preheater, combustion chamber, riser duct, rotary kiln, and grate cooler. In the preheater, the kiln feed is preheated by hot gas coming from the combustion chamber and rotary kiln. It is then partially calcined in a combustion chamber and riser duct. The feed then moves into the rotary kiln where it is superheated to approximately 1400 C to form clinker components through a process called sintering.

The heat is produced from the burning of fuel in the main burner rotary kiln and in the combustion chamber with the help of preheater exhaust Fans or Kiln ID Fans. Coal, natural gas, fuel oil, and petroleum coke are often used for firings.

Sintering is when the chemical bonds of the raw meal are broken down through heat, recombining into new compounds that form a substance called clinker. Clinker comes out of the kiln as extremely hot, small, dark gray nodules 1mm to 25mm in size. It drops onto the grate cooler for cooling from approximately 1350-1450 C to approximately 120 C through the use of different cooling fans.

Part of the hot air extracted from the cooler is utilised as a secondary and tertiary air for combustion in rotary kiln and combustion chamber, respectively.

The cooled clinker discharges from the cooler into the pan conveyor and it is transported to the clinker storage ready to be transported to the cement mills via cement mill ID fans.

At the cement mills the clinker is mixed with other additives required for producing the specific type of cement. Gypsum for OPC, limestone for limestone cement, and slag for slag cement. The ball mill then grinds the feed to a fine powder. The fine powder is then sent to a separator which separates fine and coarse product. The latter is sent to the mill inlet for regrinding. The final product is stored in concrete silos as cement.

Cement is so fine that 1 pound of cement contains 150 billion grains.

The cement is now ready for transport to ready-mix concrete companies to be used in a variety of construction projects.

Our armored fan technology provides ultra-reliable performance in cement processes from moving, mixing, heating and cooling.

If you enjoyed this article please give it a share so others can enjoy it too.