Nitrogen Dosing

Chart's liquid nitrogen dosing systems are used in the packaging of a wide range of products for preservation, pressurization and freezing. Key benefits are extended shelf life, reduced weight and enhanced product quality.

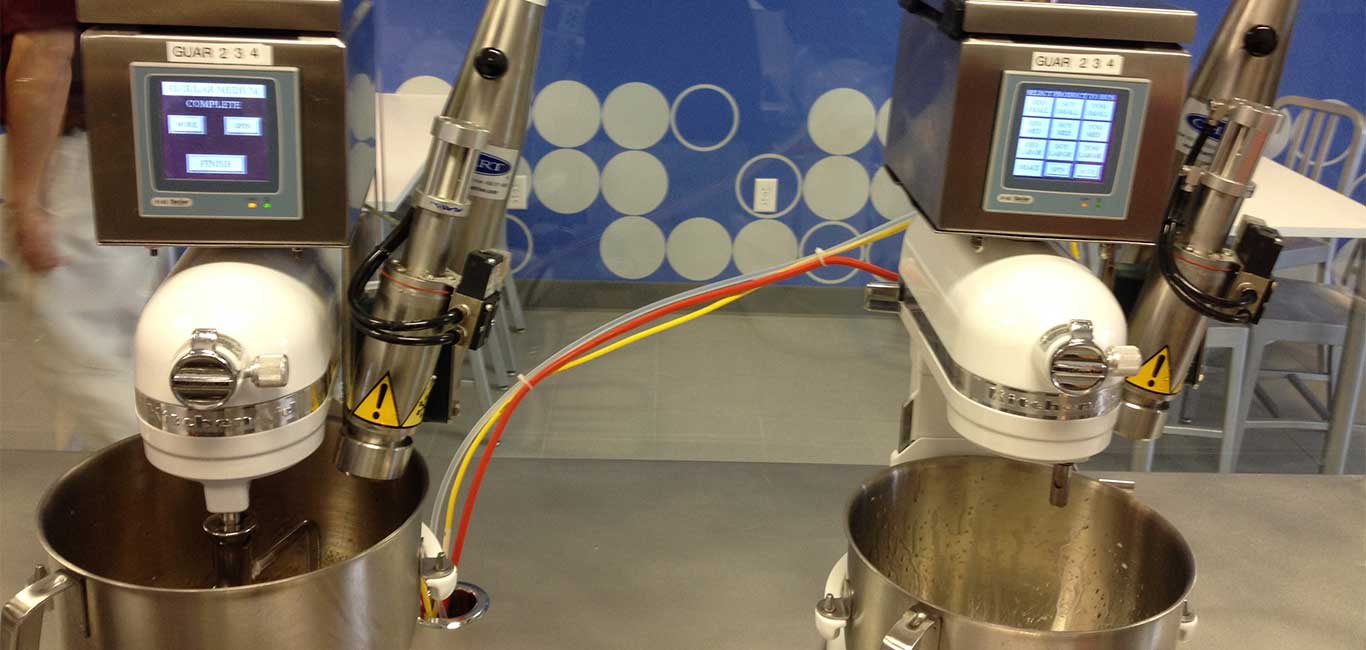

One part of liquid nitrogen (LN2) warms and expands into 700 parts of gaseous nitrogen at ambient temperature. Chart's automated dosers dispense a precisely measured dose of LN2 into each container prior to sealing. The trapped LN2 vaporizes, creating pressure, and adding rigidity to the container – allowing for a thinner container wall.

Preservation, pressurization, freezing; learn more about the 3 key features Chart nitrogen dosing systems bring to your production line and the attendant benefits in cost, efficiency and sustainability.

An exact dose of liquid nitrogen is introduced seconds before the seamer or capper. The volumetric expansion of the vaporized nitrogen pushes oxygen out of the container.

Key Benefits: oxygen reduction, extended shelf life, efficient nitrogen consumption, stabilization of organic products

Typical Applications: automobile oil, beer, condiments, wine

In Operation: documented studies show a 26% increase in shelf life and 90 to 95% reduction in headspace oxygen compared to traditional gaseous nitrogen purging

A precise dose of LN2 is delivered immediately before capping or seaming. The trapped LN2 quickly vaporizes, pressurizing the container.

Key Benefits: lighter weight packaging, increased packaging rigidity, glass to plastic transition, eliminates package paneling, ease of labeling, oxygen reduction

Typical Applications: bottled water, energy shots, flax seed oil, juices (hot and ambient fill), teas, vinegar

In Operation: documented 9 gram reduction in PET bottle weight with Chart's MicroDose™ technology. Assuming the PET resin cost of $0.80/lb and a single production line running at 700 bottles/minute, this equates to an annual cost saving >$2.6 million.

A dose of liquid nitrogen is introduced to "lock in" and surface freeze the product before it's transferred to a traditional tunnel or spiral freezer.

Key Benefits: maintains product integrity, aids in packaging and labeling, enables new products to be brought to market, enhances flavor and texture

Typical Applications: dipped ice cream cones and iCream Café

In Operation: liquid nitrogen flash freezing of ice cream cones provides stability and support through the packaging process resulting in improved overall aesthetics

A large dose of liquid nitrogen is introduced into the package seconds before the seamer or capper.

Key Benefits: extended shelf life, oxygen reduction, reduced nitrogen consumption, stabilization of organic products

Typical Applications: baby formulas, coffee, nuts, trail mix, botanicals

In Operation: 46% reduction in nitrogen consumption using a Chart doser in lieu of traditional nitrogen gas purging

Familiar with the upsurge in craft beers and the nitro coffee phenomenon? Chart nitrogen dosing facilitates both.

Keen to learn more? We provide learning opportunities through our informational webinars.

Producing and Selling Nitro Canned Beer

Discover How to Can Nitro Beers

From initial design to a complete after-sales package, we work closely with our customers to ensure that the complete system is engineered and built in accordance with their requirements and always operating at peak efficiency.

Chart Parts provides replacement components for products manufactured by Chart Industries and other manufacturers of cryogenic, CO2 beverage, LN2 dosing, water treatment, and LNG equipment. Since 2002, Chart Parts has been providing high-quality parts with customer & technical services support – so you get the right replacement parts at the right time to keep your equipment operating at peak efficiency. We leverage our OEM-approved suppliers, assuring you genuine parts at a competitive price.

View and download sales literature, technical manuals and more.

Americas - Customer Service +1 833 205 2226

Americas - Technical Service +1 800 253 1769

Europe & Middle East - Sales & Service +44 (0)1386 556622

3100000

of clean drinking water

With the donation of Chart dosing equipment Can’d Aid has provided >3.1 million cans of clean drinking water throughout the U.S., including Puerto Rico and Navajo Nation, in response to natural and human-made disasters. Can’d Aid volunteers distribute water providing access and opportunities to underserved youth, and protecting and restoring the environment.